New paper

Our latest paper has been published in JOM (Springer). It is a summary of the achievements (so far) of the ROMEO fp7 project.

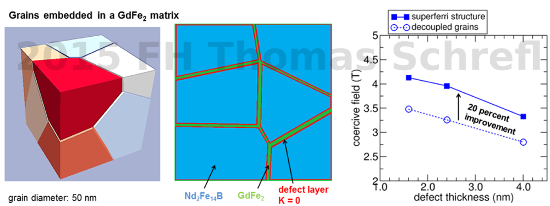

ROMEO is a project that aims to research and develop novel microstructural-engineering strategies that will dramatically improve the properties of magnets based purely on light rare earth elements, especially the coercivity, which will enable them to be used for applications above 100 degrees C.

Abstract

The rare-earth crisis, which peaked in the summer of 2011 with the prices of both light and heavy rare earths soaring to unprecedented levels, brought about the widespread realization that the long-term availability and price stability of rare earths could not be guaranteed. This triggered a rapid response from manufacturers involved in rare earths, as well as governments and national and international funding agencies. In the case of rare-earth-containing permanent magnets, three possibilities were given quick and serious consideration: (I) increased recycling of devices containing rare earths; (II) the search for new, mineable, rare-earth resources beyond those in China; and (III) the development of high-energy-product permanent magnets with little or no rare-earth content used in their manufacture. The Replacement and Original Magnet Engineering Options (ROMEO) project addresses the latter challenge using a two-pronged approach. With its basis on work packages that include materials modeling and advanced characterization, the ROMEO project is an attempt to develop a new class of novel permanent magnets that are free of rare earths. Furthermore, the project aims to minimize rare-earth content, particularly heavy-rare-earth (HRE) content, as much as possible in Nd-Fe-B-type magnets. Success has been achieved on both fronts. In terms of new, rare-earth-free magnets, a Heusler alloy database of 236,945 compounds has been narrowed down to approximately 20 new compounds. Of these compounds, Co2MnTi is expected to be a ferromagnet with a high Curie temperature and a high magnetic moment. Regarding the reduction in the amount of rare earths, and more specifically HREs, major progress is seen in electrophoretic deposition as a method for accurately positioning the HRE on the surface prior to its diffusion into the microstructure. This locally increases the coercivity of the rather small Nd-Fe-B-type magnet, thereby substantially reducing the dependence on the HREs Dy and Tb, two of the most critical raw materials identified by the European Commission. Overall, the ROMEO project has demonstrated that rapid progress can be achieved when experts in a specific area are brought together to focus on a particular challenge. With more than half a year of the ROMEO project remaining, further progress and additional breakthroughs can be expected.